DOMS Incorporated has been manufacturing high-quality suction strainers, flow diffusers, and suction filters for various OEMs for over sixty years.

Our products meet the specific needs of our clients, and our team provides the highest level of customer service. We offer a wide range of suction strainers, flow diffusers, and suction filters, and our team can help you choose the right product for your specific application. We also offer custom design services to meet your unique requirements.

A suction strainer is an essential component of a hydraulic pump. It helps to protect the pump from debris and other contaminants that could damage it. The strainer at the pump’s inlet consists of a screen or mesh that filters out foreign objects.

Sometimes, the strainer may also include a check valve to prevent backflow. Suction strainers are available in various sizes and materials and need replacement periodically to ensure that the hydraulic pump remains in good working condition.

Features of DOMS suction strainer

Protect your hydraulic pump with a suction strainer from DOMS.

- Our suction strainers come in various sizes to fit almost any hydraulic system, with capacity ratings between 5 to 200 GPM.

- The strainer separates larger particles, usually visible to the naked eye, protecting the pump from damage and premature wear.

- DOMS carries an extensive range of standard suction strainer sizes that accommodate from ½- to 4-inch O-ring, male, and female connections. So whatever your hydraulic needs, we have a suction strainer that will fit.

Applications of suction strainers

Industries use suction strainers in different applications, including:

- In manufacturing, they remove contaminants from fluids, such as oil and water.

- They are also used in HVAC systems to protect pumps from debris.

- In the food and beverage industry, suction strainers remove contaminants from liquids before they are bottled or canned.

- Suction strainers are commonly used in home plumbing systems to keep septic tanks and sewage lines clear of debris.

As you can see, suction strainers have a wide range of applications. Whether you’re looking to protect your pumps or remove contaminants from liquids, a suction strainer can help you get the job done.

Suction filters are devices used to remove debris and other particles from a fluid. They work by using a wire mesh to create a barrier that only allows fluid to pass through while trapping solid particles, helpful in preventing damage to pumps and other equipment.

In addition, suction filters can also be used to clean fluids before they are used to improve the final product’s quality and prevent contamination.

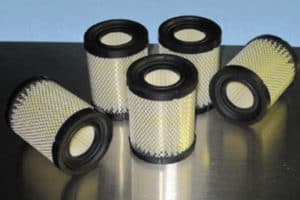

Features of DOMS Suction Filters

It’s essential to keep your DOMS pressure filter in good working order. Over time, wire mesh filters can become clogged with particulates, reducing the flow of water and straining the pump.

- Our complete line of suction filters can accommodate ½-inch to 4-inch customary female, male, and O-ring connections.

- Each filter has a crest pleat design and rounded root with end caps that have an original mechanical lock design.

- The filters have a capacity rating of 5 to 200 GPM with minimal differential loss and the ability to strain particulates as little as 10 microns.

By regularly replacing your wire mesh filter, you can help extend the life of your DOMS pressure filter and keep it working at its best.

Applications of suction filters

- Agricultural and construction industries use suction filters to help keep irrigation lines and pumps running smoothly.

- Suction filters, such as swimming pools and fish tanks, can be used in domestic settings. They keep the system clean and running efficiently by preventing leaves, twigs, and other small objects from entering the suction line.

If you’ve ever gone to a car wash, you may have noticed big machines that suction the water off your car. These suction air filters work similarly but on a much smaller scale.

They can remove water, oil, and other contaminants from the air made up of housing that contains a series of filters. The contaminated air is drawn into the housing by a suction fan then the air passes through the filters while the clean air is allowed to pass through.

Features of DOMS air filters

Robust air filters are an essential part of suction systems.

- They have a high degree of air permeability to mitigate contaminant buildup and pressure differences.

- They are constructed from stainless steel mesh or synthetic material to ensure maximum durability.

- Customers can choose advanced metal locking end caps or flexible molded end caps.

- Some designs of filters can be easily disassembled.

- All steel filters can be cleaned and reused, making them an excellent choice for suction systems that require high-quality air filters.

Applications of air filters

Suction air filters are popular in a variety of applications, including

- Vacuuming

- Dust collection

- Fume extraction

- They are also commonly used in HVAC systems to remove airborne particles.

You may have seen diffusers at your local spa or aromatherapy store, but what exactly are they? A diffuser is a device that helps disperse essential oils into the air through various methods, including heat, ultrasonic waves, and evaporation. They create a calming atmosphere, and many people find that the scent of essential oils can help to improve focus and concentration.

Features of DOMS diffusers

At DOMS Incorporated, we specialize in the manufacturing of high-quality diffusers.

- We offer a wide range of options for hardware, connections, dimensions, and other special requirements.

- Standard dimensions for our diffusers are 2 15/16” D × 4 7/16” H to 5 11/16” D × 12 ¼” H.

- Our diffusers are compatible with aqueous or non-aqueous hydraulic fluids and regular petroleum-based hydraulic oils.

- The locking dome end-caps maintain and withstand high-pressure gallons per minute (GPM).

- The diffusers can handle temperatures ranging from -60 °F to +250 °F.

Applications of diffusers

Different industries use diffusers in multiple applications.

- One common use is in aromatherapy, where diffusers disperse essential oils into the air to improve mood and promote well-being.

- Diffusers are applicable in manufacturing to distribute chemicals and other liquids evenly during production.

- In the food industry, diffusers infuse flavor into food products.

- Diffusers are used in healthcare settings to dispense medication and disinfectants.

- Many home and office environments use diffusers are also found in, which help improve air quality and eliminate odors.

As the name suggests, these filters spin onto the engine rather than being screwed on like traditional oil filters. Spin-on filters offer several advantages over traditional filters, including:

- Easier installation and removal

- Less chance of leaks

- Longer service life

- Spin-on filters are replaceable without draining the oil, making them ideal for use in vehicles with frequent oil changes.

Features of DOMS spin-on filters

At DOMS, we understand that every application is different. That’s why we offer a range of spin-on filters in different sizes:

- 3-inch

- 4-inch

- 5-inch

We also offer single and dual head configurations to meet the needs of your application. Our connection types include:

- Flange

- SAE

- NPT

- You have the option of using bypass or no bypass valves.

When maintenance is required, our visual indicators alert the operator. This way, you can be sure that your application runs smoothly and efficiently.

Applications of spin-on filters

There are many various areas and uses for spin-on filters.

- In the automotive industry, they are used to filter motor oil and hydraulic fluid.

- In the aircraft industry, they are used to filter fuel and lubricate oil.

- In the food and beverage industry, they are used to filter water and beer.

- Spin-on filters are used in water treatment plants and swimming pools.

- Chemical plants and oil refineries also use spin-on filters.

Sight gauges visually determine the level of liquid in a tank or container. On the other hand, pressure gauges measure the pressure inside a tank or system.

Both types of gauges have their unique advantages and disadvantages. Sight gauges are typically more accurate than pressure gauges, but they can be more challenging to read in low-light conditions.

On the other hand, pressure gauges are less affected by temperature and barometric pressure changes, making them ideal for use in high-pressure systems. Ultimately, the choice of gauge will depend on the specific application.

Features of DOMS sight and pressure gauges

Here at DOMS Incorporated, we offer a variety of gauges for low-pressure applications. Our hydraulic tank sight-level gauges are especially popular, as they’re not affected by sunlight or UV rays. Plus, they’re durable enough to function in harsh environments.

Applications of sight and pressure gauges

Sight and pressure gauges have a wide range of industrial and commercial applications.

- They are commonly used in the automotive industry to measure the pressure of fluids such as oil and coolant.

- They are also used in the aerospace industry to measure the pressure of fuel and hydraulic fluids.

- They are used in the food and beverage industry to measure the pressure of gases such as carbon dioxide.

- They are frequently used with other devices, such as sensors and controllers, allowing for more accurate measurements and process control.

When it comes to keeping your hydraulic fluid clean and free of contaminants, the reservoir breather filter is one of the essential pieces of equipment. Also known as an air internals filter, this device helps to keep your system clean by filtering out dust, dirt, and other airborne particulates.

Reservoir tanks install breather filters, allowing air to flow while trapping contaminants. As a result, they play a vital role in preventing contamination and extending the life of your hydraulic system.

Features of DOMS reservoir breather filters

- The filter is threaded with a quarter-turn bayonet and available with a nylon or cast aluminum cap.

- The filter can also include a pressure valve if needed.

- Pressure relief valves are essential in hydraulic systems, as they open when the filter gets dirty and start to restrict flow. Without a relief valve, the hydraulic pump could run hot or burn out.

- Not all filters come equipped with relief valves, so it is up to the OEM to request a design that mandates a filter with a relief valve installed.

Applications of reservoir breather filters

Reservoir breather filters are often used in oil and gas production and chemical and food processing.

- In oil and gas production, reservoir breather filters help to remove oil vapors and other contaminants from the air. It helps improve the finished product’s quality and prevent environmental contamination.

- In chemical processing, reservoir breather filters help remove impurities from liquids to ensure that the finished product is high quality and free of contaminants.

- In food processing, reservoir breather filters remove particles from liquids, improving the taste and safety of the finished product.

We’ve got all your filtration needs covered

Are you looking for reliable suction strainers, air filters, diffusers, spin-on filters, reservoir breather filters, or sight and pressure gauges? Look no further than DOMS Incorporated, your one-stop shop for all your filtration needs.

Our products ensure durability and performance, so you can rest assured that you’re getting the best bang for your buck. Plus, our team of experts is always on hand to answer any questions you may have about our products or the filtration process in general.

Contact us today and learn why we’re the go-to choice for many filtration needs.