Hydraulic Pressure vs. Flow

Leave a CommentRegarding hydraulic systems, two of the key concepts to understand are pressure and flow. While some people use the terms interchangeably, they actually refer to different aspects of hydraulic system operation/performance. Hydraulic flow refers to the movement of the hydraulic fluid through the system. Hydraulic pressure refers to the force of that flow when it encounters resistance. Knowing the difference between them is essential since the approach to flow control differs depending on which factor is targeted.

What Is Hydraulic Pressure?

As indicated above, hydraulic pressure is generated when the flow of hydraulic fluid through the system encounters resistance. However, it is also created by the potential energy of an object on which gravity is acting. Hydraulic pressure produced in the former situation is known as dynamic pressure, while hydraulic pressure produced in the latter situation is known as static pressure.

- Dynamic pressure is tied to a fluid’s kinetic energy per unit volume. It has a positive relationship with resistance; dynamic pressure increases as the resistance met increases. It is one of the terms in Bernoulli’s equation, which can be derived from the conservation of energy for fluid in motion.

- Static pressure is tied to fluid’s potential energy when it is trapped (i.e., wants to flow but cannot).

What Is Hydraulic Flow?

Hydraulic flow is the movement of hydraulic fluid within the system. Two related factors are flow rate and flow velocity.

- Flow rate is a measure of the movement of a particular amount of fluid within a specific time period. It is usually measured using a flow meter and can be expressed in gallons per minute or liters per minute.

- Flow velocity is a measure of the distance a specified volume of fluid travels in a specific time period. It is calculated using the cross-sectional area of the hose/pipe and the flow rate.

When discussing flow with regard to a hydraulic system, the term can have one of three meanings:

- Volumetric flow: measure of the volume of a hydraulic fluid that passes

within a specific time period - Mass flow: measure of the mass of a hydraulic fluid that passes within a specific time period

- Velocity of flow: measure of the linear speed of a hydraulic fluid as it passes a particular point within the system

Additionally, the flow of a particular hydraulic system can be classified in various ways, including:

- Steady flow: all important characteristics used to describe the behavior of the flowing fluid (e.g., density, pressure, velocity, etc.) remain constant over time

- Unsteady flow: any of the important characteristics used to describe the behavior of the flowing fluid changes over time

- Uniform flow: the velocity of flow remains constant at all points within the flowing fluid for a given time

- Non-uniform flow: the velocity of flow changes at any point within the flowing fluid within a given time

- Laminar flow: the fluid moves in layers, with one layer sliding over the adjacent layer

- Rotational flow: the fluid particles move such that they rotate around their own axes

Learn More About Hydraulic Pressure and Flow From DOMS Incorporated

Want to learn more about hydraulic pressure and flow? Ask the experts at DOMS Incorporated! As a leading provider of hydraulic equipment components, our knowledgeable team members are ready and willing to answer and address any questions or concerns you may have about these topics. Contact us today! Additionally, if you need hydraulic components, we are also more than happy to help. Request a quote to discuss your equipment needs.

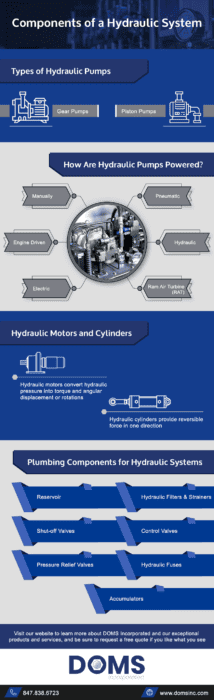

Key Components of a Hydraulic System

Leave a CommentHydraulic systems use compressed hydraulic fluid to create and distribute the power needed to drive or move connected equipment. They are integrated into the devices and systems of a wide range of industries and applications, from aircraft doors in the aerospace industry to production machines in the manufacturing sector.

While the design and construction of hydraulic systems may vary to suit the specific needs of an application, all units operate under the same basic principle—i.e., force applied at one point will be transmitted through the hydraulic fluid to another point (note: for this principle to hold true, the fluid utilized must be incompressible, which means it should not change in volume when it is compressed). Additionally, they have the same key mechanical components: a hydraulic pump, a hydraulic motor or cylinder, and plumbing. Below, we provide an overview of these three components.

Hydraulic Pumps

In hydraulic systems, pumps are used to apply pressure to the hydraulic fluid. There are many types of hydraulic pumps available, each of which offers unique characteristics that make them suitable for different applications. For example:

- Gear pumps utilize meshing gears to pump a fixed amount of fluid per rotation. They are best suited for low-pressure hydraulic systems (under 1,500 psi).

- Piston pumps use a piston within a cylinder to move fluid. They are available in fixed displacement and variable displacement variations; the former move a specific amount of fluid per stroke, while the latter alter fluid output to compensate for changes in system demand.

These pumps can be powered in a variety of ways, including:

- Manual: the pump is powered manually (e.g., by human-operated pedals or hand levers)

- Engine driven: the pump is mounted on the engine accessory gearbox

- Electric: the pump is powered by an AC or DC motor

- Pneumatic: the pump is powered by air-powered motors

- Hydraulic: the pump is powered by another hydraulic system via a power transfer unit (PTU)

- Ram Air Turbine (RAT): the pump is powered by a ram air turbine that extends into the airstream to produce hydraulic pressure

Hydraulic Motors and Cylinders

Once the pump has pressurized the hydraulic fluid, hydraulic motors and cylinders use the pressurized fluid to perform mechanical work.

- Hydraulic motors convert the hydraulic pressure and flow into torque and angular displacement or rotation. They are available in numerous variations, including gear, vane, and radial piston.

- Hydraulic cylinders provide reversible force in one direction. They consist of a piston connected to a piston rod inside of a cylinder. The hydraulic pressure moves the piston and piston rod back and forth within the cylinder.

Plumbing Components for Hydraulic Systems

The plumbing ensures the hydraulic fluid moves through the hydraulic system as needed. It consists of a variety of components that perform different functions, including:

- Reservoir: holds the amount of hydraulic fluid necessary to operate the hydraulic system

- Hydraulic filters and strainers: removes contaminants from the hydraulic fluid that could compromise the functionality and reliability of the hydraulic system

- Shut-off valves: serves as a safety measure that prevents the ignition of the hydraulic fluid

- Control valves: controls the directional flow of the pressurized hydraulic fluid

- Pressure relief valves: ensures the hydraulic system does not exceed the nominal system pressure

- Hydraulic fuses: automatically seals off the hydraulic line if pressure drops below a certain threshold

- Accumulators: stores pressurized hydraulic fluid that can be used to quickly and temporarily supplement force in the system in the event of sudden high demand or pump failure

Learn More About Hydraulic Components From DOMS Incorporated

From pumps to motors and cylinders to plumbing, each component within a hydraulic system is essential to achieving smooth and reliable system operation. To learn more about these components and their functions, contact the hydraulic equipment experts at DOMS Incorporated today. If you need components for a hydraulic system, request a quote.