For more than 60 years, DOMS Incorporated has served OEM industries with quality suction filters, strainers, and flow diffusers. Located in Genoa City, WI, we’ve created a loyal and ever-growing customer base by combining top-notch service with impeccable quality control.

We are proud to add a new line of spin-on filters to our catalog of hydraulic filtration products. Spin-on filters help prevent contamination in hydraulic systems, such as fuel transfer lines, cooling circuits, lube oil systems, power transmissions, compressors, and hydrostatic charge pumps.

What Is a Spin-On Filter?

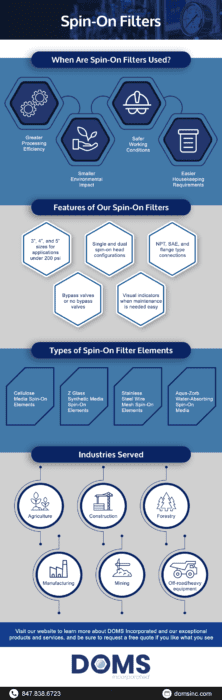

When Are Spin-On Filters Used?

Spin-on hydraulic filters help achieve and maintain high cleanliness levels in hydraulic systems, which can benefit a facility in many ways, such as:

- Greater processing efficiency

- Smaller environmental impact

- Safer working conditions

- Easier housekeeping requirements

However, they must be used in the right application. They are best suited for systems with low- to medium-pressure conditions that do not experience any high-pressure surges. Additionally, since the filter element is disposable and affordable, they are ideal for applications that require regular filter replacement to ensure proper system operation and uncompromised component integrity.

Features of Our Spin-On Filters

Our spin-on filters work with various hydraulic fluids, including fuel, oil, glycol water, emulsions, and synthetic compounds. These canister filters efficiently prevent particle buildup across a wide array of applications. They are available in/with:

- 3”, 4”, and 5” sizes for applications under 200 psi and other options for higher-pressure applications of up to 500 psi

- Single and dual spin-on head configurations

- NPT, SAE, and flange type connections

- Bypass valves or no bypass valves

- Visual indicators to make knowing when maintenance is needed easy

Types of Spin-On Filter Elements

- Cellulose Media Spin-On Elements: Used with petroleum-based fluids, this traditional paper-based medium provides a foundation of filtration and capacity.

- Z Glass Synthetic Media Spin-On Elements: Providing the highest level of depth filtration and capacity, this multilayered nonwoven glass media imbues your products with longer service lives.

- Stainless Steel Wire Mesh Spin-On Elements: These precisely woven patterns offer the basic surface filtration needed for pump protection.

- Aqua-Zorb Water-Absorbing Spin-On Media: This material absorbs and retains free water from petroleum-based fluids.

Industries Served

Some of the industries that regularly rely on spin-on filters to protect their hydraulic systems include:

- Agriculture

- Construction

- Forestry

- Manufacturing

- Mining

- Off-road/heavy equipment

These industries make up a significant slice of our client base, but we’re proud to work with any industry desiring our custom filtration solutions. No job is too big or too small! We offer production volumes ranging from 1–100,000 units, and we typically achieve lead times of four to six weeks. We also stock inventory by request.

Spin-On Filters vs. Suction Filters

Industry professionals utilize many different filtration technologies to protect hydraulic systems from contaminant damage. Two of the most commonly used are spin-on filters and suction filters. While both technologies rely on similar principles, they are suitable for different applications. For example:

- Spin-on filters are best suited for low-pressure systems with high flow capacities, while suction filters are suitable for use in systems where pressure surges may occur (as long as pressure tolerances are appropriately considered to prevent cavitation).

- Spin-on filters are ideal for applications where convenience and cost are critical due to their easy installation and replacement requirements, while suction filters are more appropriate for applications where easy maintenance requirements are critical due to their easy-to-clean rounded root and crest pleat design.

Superior Filtration Products and Services at DOMS Incorporated

At DOMS Incorporated, we provide filters, strainers, and return-line flow diffusers according to custom specifications or drawings. We also manufacture unavailable, discontinued, and/or custom suction filters, strainers, and return-line flow diffusers. We will gladly furnish a unit for inspection, testing, and evaluation at no cost to you!

Our team is committed to exceeding customer expectations. By providing top-quality products at competitive prices to OEMs, we keep clients coming back year after year.

Visit the rest of our website to learn more about DOMS Incorporated and our exceptional products and services, and be sure to request a free quote if you like what you see.