Hydraulic systems rely on a variety of filters to keep process fluids clean and protect sensitive system components. Suction filters play an important role in this filtration process by capturing suspended particulates and pollutants as fluids pass through them and into the pump. Located within the pump’s hydraulic reservoir, they act as the last line of defense against debris entering the pump and potentially causing component damage or system failure.

Hydraulic systems rely on a variety of filters to keep process fluids clean and protect sensitive system components. Suction filters play an important role in this filtration process by capturing suspended particulates and pollutants as fluids pass through them and into the pump. Located within the pump’s hydraulic reservoir, they act as the last line of defense against debris entering the pump and potentially causing component damage or system failure.

In this article, we address some commonly asked questions regarding the use of suction filters in hydraulic systems.

What Is the Function of a Hydraulic Filter?

Suction filters are one of the many types of filters that help keep hydraulic systems in optimal condition. Most systems integrate multiple filters that are installed in various locations to keep fluids clean as they move through the hydraulic circuit. These filters work together to remove the millions of particles larger than 1 micron (.001 mm) that enter the hydraulic system every minute of its operation. As these particles can cause damage to the system’s components and hydraulic fluids are so easily contaminated, it is critical to design a hydraulic filtration process that is effective and efficient at protecting the system and, consequently, improving its lifespan.

Where Should a Suction Filter Be Located in a Hydraulic System?

Proper placement of filtering elements in a hydraulic system is key to successfully preventing the infiltration of solid foreign matter and the subsequent system damage. However, the location is subjective; where a filter should be installed depends on the type of filter.

For example, suction filters are designed to protect the pump from particulates in the reservoir. Therefore, they should be installed on the suction port or pipeline of the pump. On the other hand, inline filters are designed to filter fine particulates from the fluid stream before it flows back into the reservoir. Therefore, they should be installed within the fluid return line of a hydraulic system. When these filters are positioned correctly, the pressure of the return flow is strong enough to force fluid through the filter’s fine screen but not so strong that a more complicated filter design or housing is required.

Do Suction Filters Carry the Risk of Cavitation?

Hydraulic systems have complex pressure profiles that must be taken into consideration during the installation of filtration elements. In terms of filtration efficiency, the flow and pressure conditions surrounding the pump intake make it an optimal location for a suction filter. However, hydraulic pumps are extremely sensitive to restrictions in the intake line, and suction filters have the potential to cause cavitation and mechanical damage if not designed and maintained properly.

One of the main ways suction filters can trigger cavitation is by becoming clogged with debris, which causes a pressure increase in the suction line. Fortunately, this risk can be mitigated in the following ways:

- Following proper filter maintenance. Cleaning or replacing the suction filter on a regular basis is vital to ensuring the fluid’s pressure remains within a safe range.

- Installing a relief valve. Suction filters can be equipped with relief valves that activate in response to increasing pressure. These valves help protect the pump from damage, even when the filter becomes clogged.

<Learn more about out why suction filters are used in used hydraulic systems.>

How Often Should You Change Hydraulic Suction Filters?

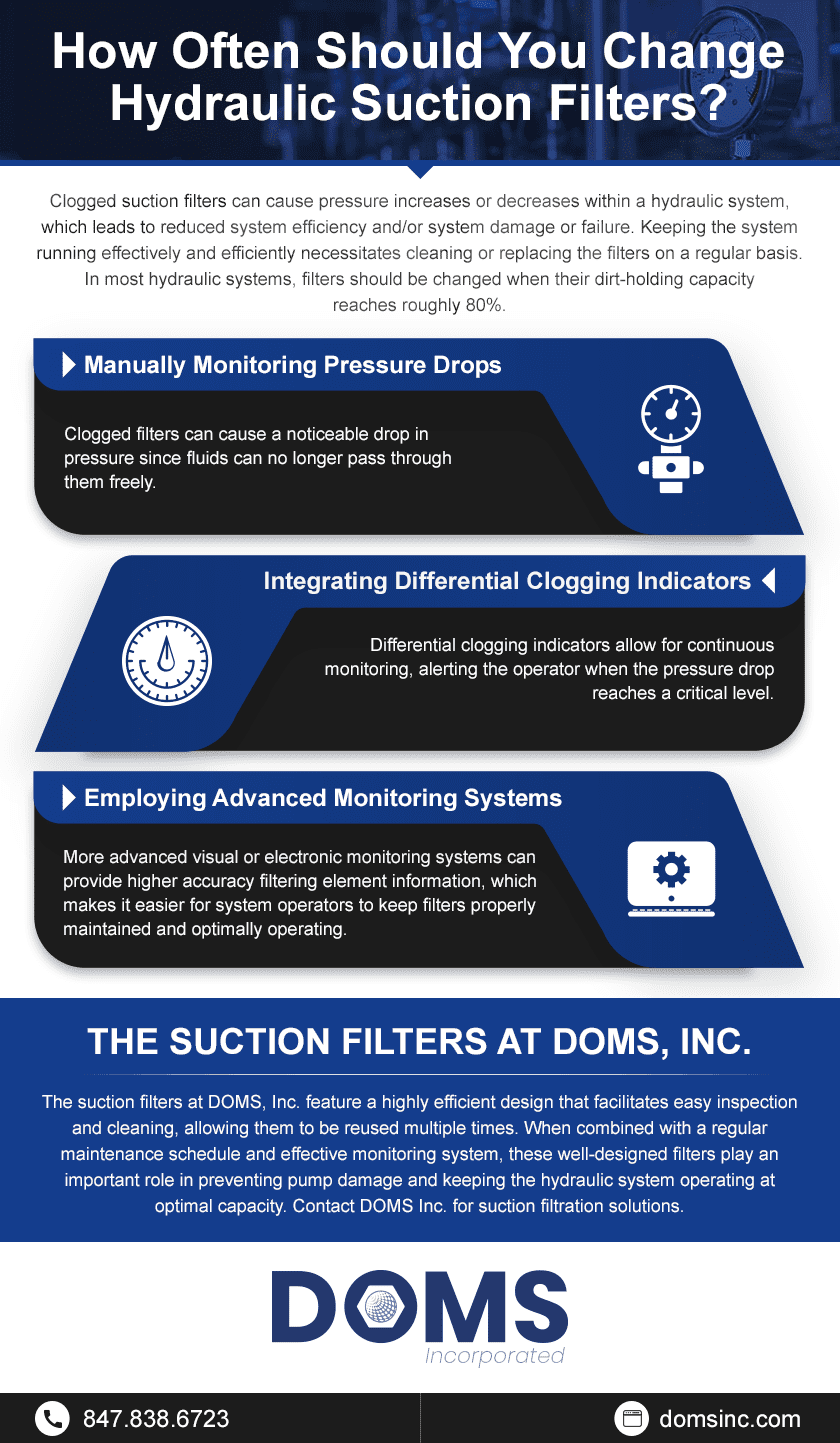

Clogged suction filters can cause pressure increases or decreases within a hydraulic system, which leads to reduced system efficiency and/or system damage or failure. Keeping the system running effectively and efficiently necessitates cleaning or replacing the filters on a regular basis. In most hydraulic systems, filters should be changed when their dirt-holding capacity reaches roughly 80%.

There are several approaches to gauging the condition of a suction filter:

- Manually monitoring pressure drops. Clogged filters can cause a noticeable drop in pressure since fluids can no longer pass through them freely.

- Integrating differential clogging indicators. Differential clogging indicators allow for continuous monitoring, alerting the operator when the pressure drop reaches a critical level.

- Employing advanced monitoring systems. More advanced visual or electronic monitoring systems can provide higher accuracy filtering element information, which makes it easier for system operators to keep filters properly maintained and optimally operating.

The suction filters at DOMS, Inc. feature a highly efficient design that facilitates easy inspection and cleaning, allowing them to be reused multiple times. When combined with a regular maintenance schedule and effective monitoring system, these well-designed filters play an important role in preventing pump damage and keeping the hydraulic system operating at optimal capacity.

What’s the Difference Between a Suction Filter and a Suction Strainer?

Suction filters and strainers are both designed to remove solid contaminants from process fluids, protecting downstream equipment from damage and improving system efficiency. However, despite sharing some functional similarities, filters and strainers are two distinct components with different operating principles. The main differences between them include:

- Size of particles being removed: Featuring a coarse mesh screen, strainers are designed and positioned to capture larger particles from process fluids as they flow into the hydraulic pump. On the other hand, filters have finer screens that are effective for trapping smaller particulates before they enter the pump.

- Flow resistance: Strainers provide low resistance to fluid flow, creating a relatively small pressure drop as fluids pass through them. In contrast, fluids passing through the finer screens of filters will typically experience a noticeable pressure drop.

Contact the Suction Filter Experts at DOMS Incorporated Today

Suction filters play an essential role in preventing particles from entering hydraulic pumps and causing component damage or system failure. However, they must be well-designed and properly maintained to work as intended. Partnering with an experienced filtration solutions provider can ensure you receive the right filtering element for your system and application.

At DOMS Incorporated, we manufacture high-quality suction filters, strainers, and flow diffusers for a wide range of OEM industries. Our suction filters are carefully designed to protect hydraulic pumps, ensuring consistent system performance and enhanced system longevity. The superior performance of these filters comes from their unique design, which includes the following features:

- Rounded root and crest pleat design. Traditional suction filters feature an accordion-style peaked pleat design, which is inherently inefficient and challenging—and occasionally impossible—to clean. Our suction filters utilize an easy-to-clean rounded root and crest pleat design that allows for 100% filter area utilization to overcome these limitations. In addition to enhancing efficiency, the specialized design allows the filter to be reused over and over.

- End caps with a unique mechanical lock design. Our filters have end caps that are flared for a tapered channel construction. The cap, center core, and element are assembled with a high-strength, two-part epoxy resin adhesive, forming a robust filtration unit that can withstand extreme vibration, shock, and other harsh hydraulic system operating conditions.

- Optional relief valves. For enhanced system protection, our suction filters can be equipped with relief valves upon request. These valves automatically activate in response to pressure buildup, which helps prevent pump damage when filters become clogged or blocked.

With both standard and custom filtration options available, we can work with you to find a personalized solution that optimizes your hydraulic system’s efficiency and protects the pump from damage. To learn more about our specific products and services, check out our suction filters page or contact us today. To discuss your suction filter requirements with one of our experts, request a quote.