Hydraulic systems serve a versatile range of needs for machinery and heavy equipment. Unfortunately, the presence of small debris or particulates can cause irreversible damage to a hydraulic system if left unchecked. Over time, this ruins system efficiency and longevity. Before going over the details regarding types of hydraulic filters and strainers that can prevent contaminants from entering the hydraulic system, here is a brief review of the basic components of a hydraulic system:

- Reservoir – holds hydraulic fluid that powers the whole system

- Filter – prevents contaminants from entering the system

- Pump – moves hydraulic fluid throughout the system

- Lines – tubes, pipes, and/or hoses that transport fluid to/from the hydraulic cylinder

- Control valve – extends/contracts the cylinder

- Hydraulic cylinder – creates linear motion in the system

Particles or contaminants may enter into a hydraulic system for a number of reasons, such as a seal failure. However, the most common occurrence is during routine maintenance when a cap or seal is removed.

To prevent any substances from entering the system, the right type of hydraulic filter should be used at all times. The filter will remove any contaminants that may have entered from a previous cycle before returning the fluid to the reservoir to ensure the system always has clean fluid. Depending on the system, the hydraulic filter may be located in the reservoir or just before it somewhere on the return line.

Guide To Hydraulic Filter Types

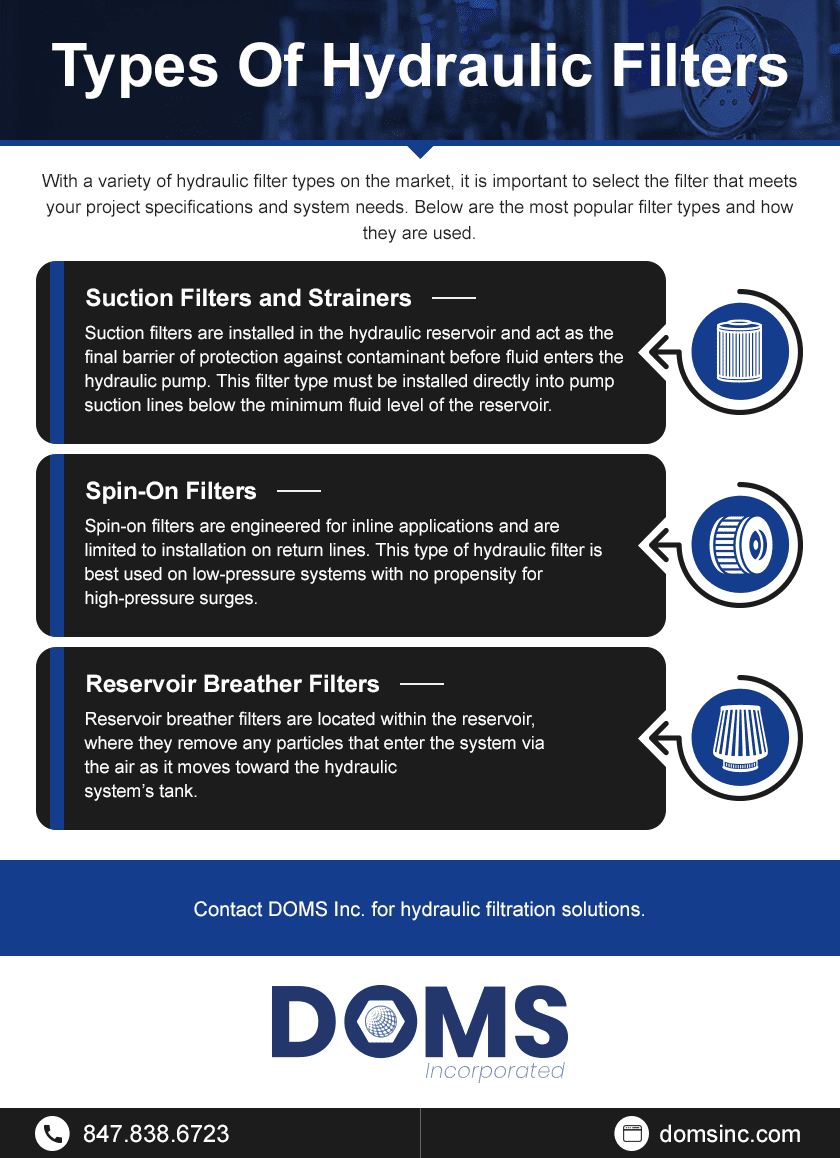

With a variety of hydraulic filter types on the market, it is important to select the filter that meets your project specifications and system needs. Below we will explain the most popular filter types and how they are used.

Suction Filters and Strainers

Suction filters are installed in the hydraulic reservoir and act as the final barrier of protection against contaminant before fluid enters the hydraulic pump. This filter type must be installed directly into pump suction lines below the minimum fluid level of the reservoir. Suction filters feature simpler maintenance than strainers and provide cost-effective protection to the hydraulic system.

Of note, suction filters do not protect downstream components from pump wear debris. Some variable-volume pumps also may not be appropriate for suction filters.

Spin-On Filters

Spin-on filters are engineered for inline applications and are limited to installation on return lines. This type of hydraulic filter is best used on low-pressure systems with no propensity for high-pressure surges. When used on the correct system, spin-on filters offer an economical, low-maintenance choice for hydraulic filtration.

Reservoir Breather Filters

Reservoir breather filters are located within the reservoir, where they remove any particles that enter the system via the air as it moves toward the hydraulic system’s tank.

Additional Hydraulic Filters

Aside from the aforementioned filters, you may also see occasional references to bag filters or duplex filters. However, these are not common and will be written into the specifications of your hydraulic equipment if you need them.

What Type of Hydraulic Filter Do I Need?

The best type of hydraulic filter is entirely dependent on the construction of the system. A filter that operates on a pressure line must withstand a higher pressure than the line puts out to ensure successful operation. For example, a return line filter will typically only withstand the back pressure of the flow. The back pressure fluctuates due to the intensity of the flow and the pressure differential a clogged element creates. If the return line filter does not slightly exceed the maximum back pressure, the filter will not operate correctly during normal pressure fluctuations.

Hydraulic Filters From DOMS, Inc.

Any hydraulic system in operation needs an appropriate hydraulic filter or strainer installed to extend the life of the system and protect its efficiency. To get the appropriate filtration equipment for your system, please do not hesitate to request a quote or contact us with any questions you may have.